Why Upgrade Your Legacy PLCs?

- Lower Operational Costs

Modern PLCs require less maintenance, consume less energy, and offer better diagnostics, reducing downtime and service expenses. - Improved Performance & Speed

New systems process data faster, support advanced automation features, and integrate seamlessly with modern SCADA, MES, and ERP platforms. - Enhanced Reliability & Uptime

Avoid unexpected failures and parts shortages by replacing aging hardware with robust, supported technology. - Future-Proof Your Infrastructure

Modern PLCs support remote access, cybersecurity protocols, and flexible expansion, keeping your operations ready for tomorrow’s demands. - Simplified Compliance & Reporting

New platforms make it easier to meet regulatory standards and generate reports for audits, safety, and sustainability.

Our Migration Process

-

Assessment & Planning

We evaluate your current system, identify risks, and design a migration strategy tailored to your goals. -

Hardware & Software Mapping

We match legacy I/O and logic to modern equivalents, ensuring functional continuity and performance improvements. -

Implementation & Testing

Our engineers handle installation, programming, and validation, ensuring your new system is production-ready. -

Training & Support

We provide documentation, training, and ongoing support to help your team operate and maintain the new system confidently.

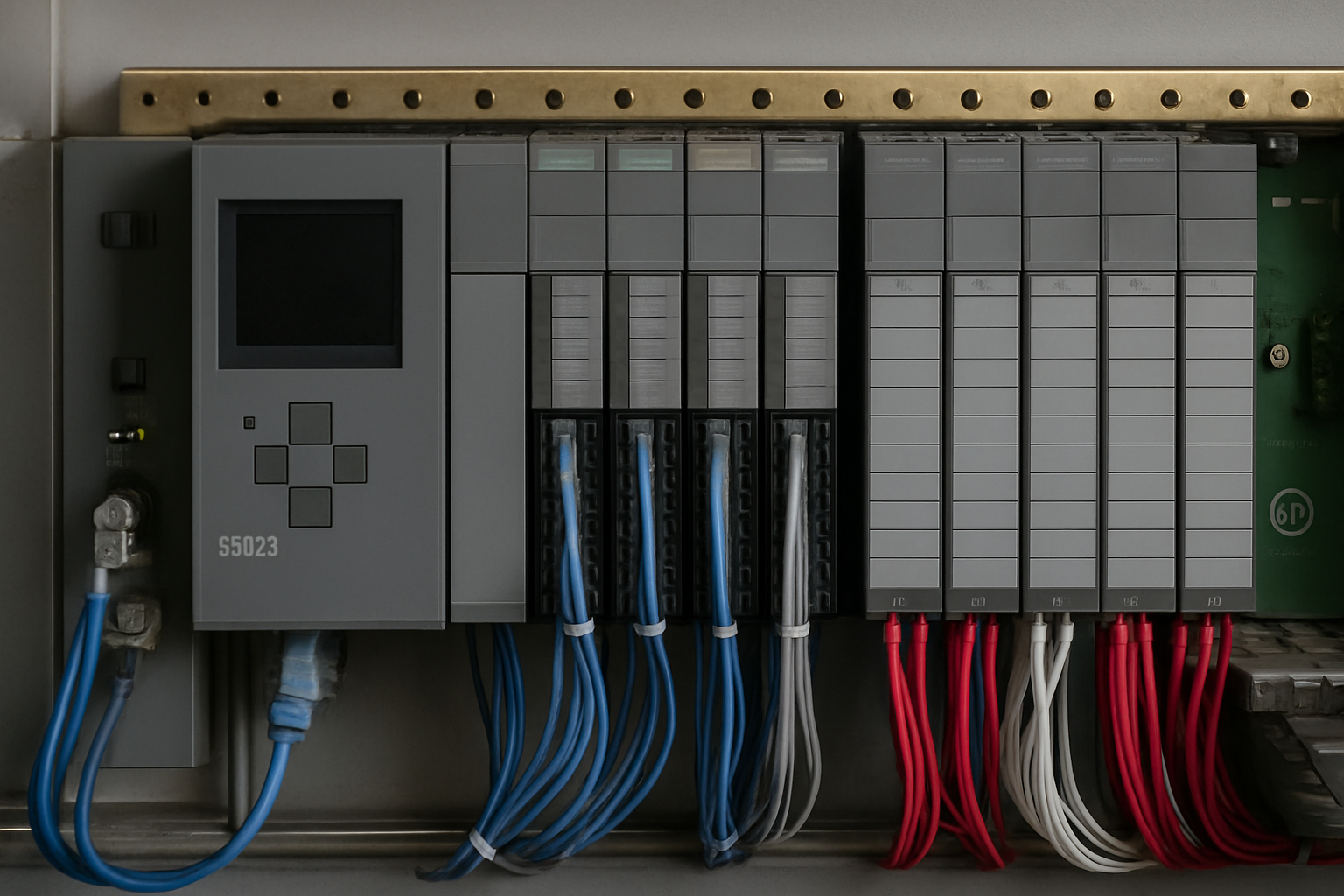

The following are some of the legacy PLCs we support. These are some more of the common ones, but we support many more than these. If you're curious if we support your particular PLC, reach out to us at sales@salemautomation.com.

- Allen Bradley PLC-5

- Allen Bradley SLC 500's

- Siemens S7-200 and S7-300 PLC's

- Omron C series controllers

- GE 90-30 and 90-70 PLC's

- Square D Sy/Max controllers